France attracted 78.95 million foreign tourists in 2010, making it the most popular tourist destination in the world. Almost 10% of them go to visit the Eiffel tower. On an average there are more than 19 000 visitors (at peak more than 100 000 visitors/day) at the Eiffel tower daily. The location is very busy and in the heart of Paris. But even the busiest buildings have to be refurbished.

Background of The Eiffel Project

From June 2012, the historic Eiffel Tower was planned to undergo massive renovations on its first level in an effort to update that level's viewing pavilion and make the area more appealing to visitors. The first level of the Eiffel Tower had not seen renovations in over 30 years, so the work was necessary.

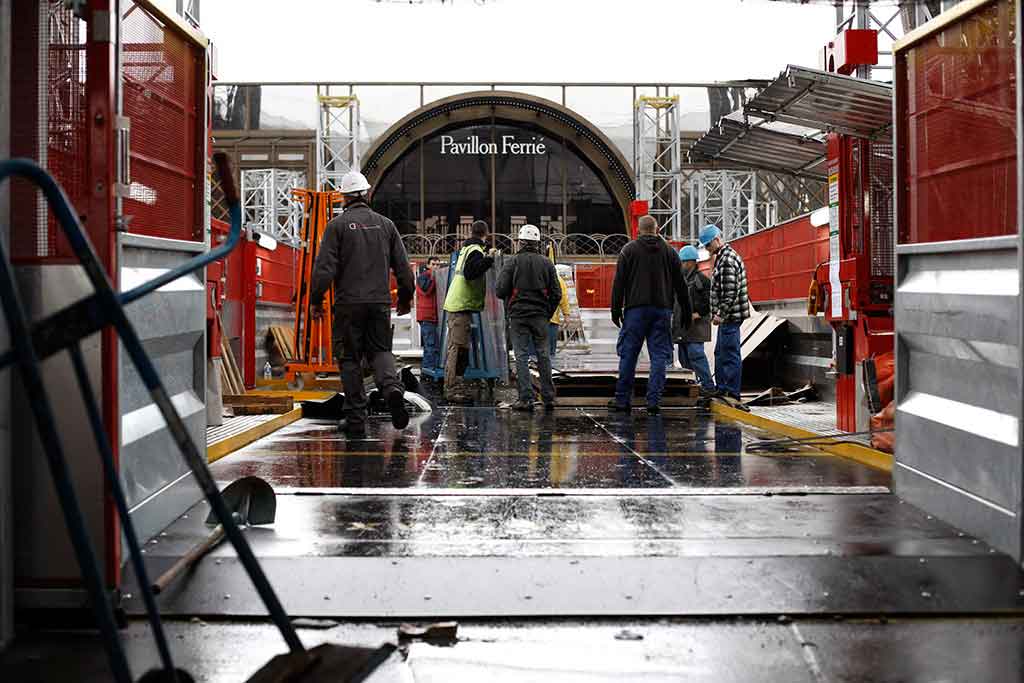

The number of visitors and very strict safety, environment, aesthetics etc. rules and statutes etc. at Eiffel made this target very challenging. Also the available work area at the first floor is very small and access for equipment, materials and personnel is extremely limited.

Bateg, a Vinci Company, won the contract with the help of Scanclimber and its French rental customer Sky Acces.

From June 2012 to June 2014 Bateg is renovating the first floor using Scanclimber's Monster Platform which is anchored only at height of 50 meters.

The Platform Design

The platform design for the Eiffel project started from Scanclimber's twin mast SC8000 mast climbing work platform. The idea was to use as many standard components as possible to make the product on schedule and save costs for the customer.

Scanclimber designed a solution using two twin mast SC8000 units with an additional middle platform extension placed between them. This provided a 24.1 x 6.6 m floor area and 9 tonnes of capacity. Finally, this mast climbing work platform was approved as a transport platform.

In the final product, more than 90% of the platform is made of standard components. Considerable cost savings were achieved and spare parts are readily available.

The Platform

The size of the Eiffel Monster platform is 24.1 meters long and 6.6 meters wide (Compare with a tennis court for single matches: length 23.78 meters and width 8.23 meters.)

- Loading capacity: 9000 kg

- Floor height: 1-57 meters

- Speed: 8.4 m/min

- Max. wind speed in operation: 20 m/s

- Ties: at 50 meters only

Masts

In each corner of the platform there is a mast, in fact, one mast is a cluster of three standard SC8000 masts. The four mast clusters stand on the platform's four corners. The masts are bound together with specially developed triple mast connectors.

As the platform stands in the middle of the Eiffel tower, the lowest possible anchoring points are 50.6 m above the ground level. Each of the 60 m high masts are tied only once, because the first floor of the Eiffel tower is at the height of 57 meters, just 7 m above the anchoring level.

The City of Paris required protection of the Eiffel Tower frame due to it's historic nature. As the frame cannot be damaged, welded or even marked, by the anchor fixings, anchors are fastened to the Eiffel Tower with special clamp fixings.

With its size of 162 m2 the platform's huge sail. + added mast surfaces. The mast sections had to be designed with enhanced stiffness and their groundings are 12 m deep. Thus the platform can be in operation even during wind speeds of up to 20 metre/second and can withstand up to 44 metre/second when out of operation. The wind speed in operation exceeds the standard SC8000 figure with 30%.

Foundations

The foundations weigh 25 tonnes each, and are made of two parts: The insert, which sits below the ground level, and the top plate which is bolted onto the top of it. The foundation is set with concrete and the mast bases are welded onto the foundation's top plates.

Aesthetics played an important role in this project. The appearance of the platform with the masts was expected to merge into their surroundings as much as possible. The mast clusters and the platform stay now in aesthetic harmony.

Due to time constraints and concerns that moving the platform in the day would cause too much noise pollution, the original plan was to raise the platform once early in the morning and then drive it down in the evening. The noise was cut with the clever design by 25% and the speed increased by 33%. Bateg is able to go up and down not only once but 3-4 times in a day.

Project Safety

Work safety and also visitors safety as an extra factor is perhaps the most important concern of the project.

The site worker's safety

For the site workers' safety, railings at a height of 2 m are placed around the platform during the time it is used. There is also a hard roof above the control station to protect the operator from falling objects. The 3.2 m wide platform loading door can only be used at the ground level. The loading door is automatically locked until the platform returns to ground level.

Hydraulic ramps (2 m long, 3 m wide), with a 1500 kg capacity, at each end of the platform are used to move personnel, materials and equipment between the platform and the first floor of the Eiffel tower. The ramps are prevented from opening until the platform has reached the first floor.

A landing door (2 m high) is bolted onto the Eiffel tower at the first floor. The landing door can be opened only from the platform side. For additional safety an emergency opening is provided from the floor side as well.

The visitors safety

Work on the platform and the Eiffel tower pavilion goes on and at the same time the public queue up beneath it and use the Eiffel visitor's lifts to visit the other areas of the building. All work tools have to be securely fastened when they are not in use and the work area, including the platform, is completely secured with 2 meters netting.

RU

RU  PL

PL  FR

FR  DE

DE  EN

EN