Two L-shaped twin mast climbing work platforms were used to build the concrete water tank at the world’s tallest wind mill. A unique mast climber solution was designed for the construction work of the world’s tallest wind turbine tower near Stuttgart, Germany.

About the Project

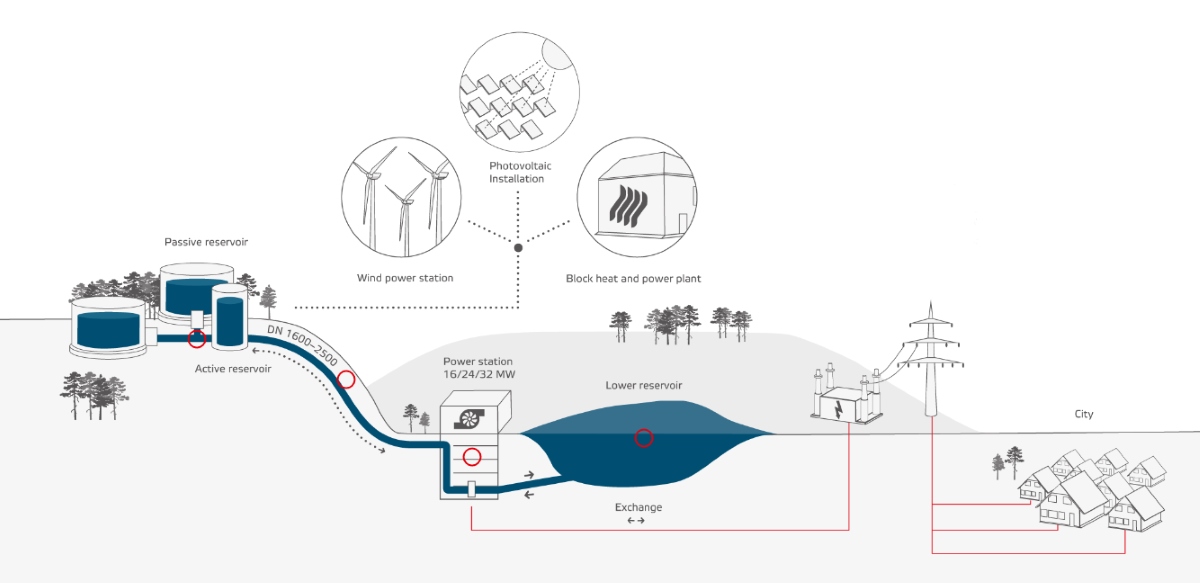

Max Bögl, a company known for its pioneering efforts in designing state-of-the-art wind turbines, kicked off a project in Gaildorf, Germany. The project comprises three turbines with a hub height of up to 178 meters and a world record of 246.5 meters to the top of the rotor. The project also incorporates a unique ‘water battery’ concept. A water battery is an innovative combination of renewable energies like Wind, PV or biomass with a pumped storage hydropower plant enabling the creation of a high performance storage solution. It consists of an upper active and passive water tank in combination with the wind tower and a hydropower plant and a lower reservoir. An unique PE penstock connects the upper and lower reservoirs.

The water battery serves as a short-term storage and makes a contribution to the electric grid. The load peaks can be lowered by peak shaving which saves expenses related to power. The hydropower plant can change between storing and producing energy within 30 seconds when required.

Scanclimber MCWPs were used to build the 40-meter-high inner tanks.

Challenges

The main challenge in this project was to install the concrete elements to build the 40-meter–high storage tank inside the wind mill tower. Traditional scaffolding methods were insufficient for building a storage tank of this magnitude and shape. A solution using four mast climbers in a single mast arrangement was ruled out for safety reasons.

Two twin L-shaped platforms connected at 90 degrees

After a careful analysis and consideration of the project requirements, Scanclimber’s team came up with a design of two SC8000 MCWPs in an L-shape configuration on twin masts. For the first time ever, the platform sections were connected in L-shape form at 90 degrees using special adapters and twin hinges. A platform length of 30 meters was achieved with a payload capacity of 5600 kg.

The concrete element installation work normally requires two persons working on one platform. By using two twin platforms configurations instead of four single platforms, the personnel requirement could be halved; from eight to four.

| Project Facts | |

|---|---|

| Location of the Project | Gaildorf in Germany |

| Main Contractor | Max Bögl |

| Machines used | Mast climbing work platform in a twin arrangement |

| Models | 2 x SC8000 |

| Length of platform | 30 m |

| Max. working height | 40 m |

| Platform payload | 5600 kg |

| Main use of the platforms | Concrete work for storage tank |

| Special features | Twin platforms connected at 90 degrees |

RU

RU  PL

PL  FR

FR  DE

DE  EN

EN